YT-BZR-3 PP woven bag heat sealing machine

YT-BZR-3 PP woven bag heat sealing machine

product description

product description

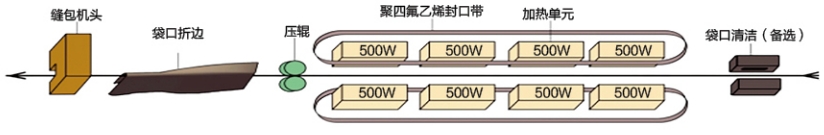

Working process:

Working process of heat sealing and sewing: bag mouth cleaning (optional) - heat sealing of inner bag(heating of four groups of heating blocks: Teflon sealing tape prevents the heating block from contacting the bag directly, so as to protect the bag surface from adhesion with the heating block)-* pressing roller pressing*bag opening folding -*sewing machine: sewing characteristics of outer bag: this unit uses controller, motor frequency conversion speed regulation controller and heating system detection device to form the main bod of the control system, Realize the coordinated control of the whole heat sealing machine.The system has the functions of heating system detection, automatic alarm shutdown, fault display,and perfect fault protection and interlock shutdown. The entire operating system is simple to use, complete in function, and easy to repair and maintain. The whole machine is composed of an automatic induction device, an automatic heat sealing device an automatic folding sewing device and a field control cabinet,.Realize the integration of heat sealing inner membrane and outer bag folding seam, effectively improve work efficiency and reduce labor costs.

Technical Parameters

Technical Parameters | Heat sealing speed | 9-14m/minute |

| Heating block power | 0.5x8kW |

| Sealing machine power | 0.55kW |

| Sewing machine power | 0.4kW |

| Bag mouthcleaner power | 1.5kW(Optional) |

| Total power | 6.5kW |

| Machine size: length x width x height | 3230x1090x2052mm |

| Gross weight | About 650KG |

| Sewing head model | YTDS-9C GK35-6A |

| Sealing height(mm) | 800~1700(from ground) |

| Sealing temperature | 0-400℃ |

| Application | Woven bag, inner bag with PE film, Out side with bag folding function |

Product inquiry

Product inquiry

All rights reserved:COPYRIGHT © 2017 Tianjin sewing(Tianjin) Automation Technology Co., Ltd 津ICP备20003426号-1 Technical Support:onnuoIAD